A-306, Lingnan Innovation Valley, Baoan District, shenzhen, China 518108

Phone:

+86 075526918186

Email:

info@iborescope.com

Basic working principle, characteristics and application of industrial borescope

Introduction to the working principle and application scope of industrial borescopes

(1)Features of industrial borescope

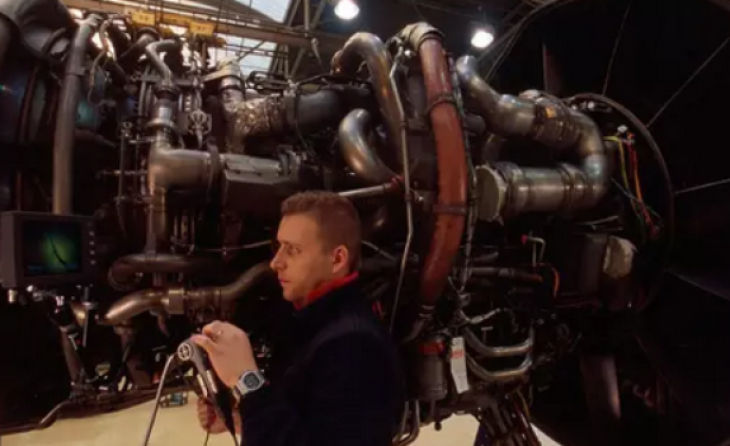

An industrial borescope is a non-destructive testing instrument classified as visual inspection (VT). It is used to observe the internal surface of objects that cannot be directly viewed by the naked eye. This detection method has the characteristics of non-destructive and simple operation. It saves the tedious disassembly and assembly process and avoids damage to the structure of the detected object. It can effectively improve the detection efficiency.

(2)How industrial borescope work

(3)The scope of application of industrial borescope

Industrial borescopes are widely used. It can be used in aerospace, energy industry, petrochemical industry, automobile manufacturing, machinery manufacturing, special inspection industry, food and medicine machines, police safety, military equipment, automotive aftermarket and other fields. Common applications of industrial borescopes are the detection of core components such as aero-engine combustion chambers, compressors, blades, and turbines. As well as testing of auto parts such as engine, cylinder block, cylinder head, crankshaft, etc., and testing of electrical equipment such as gearboxes, bearings, pipes, and valves.